- Ana Sayfa

- Reverse Engineering & Product Design

Reverse Engineering & Product Design

Reverse Engineering & Product Design

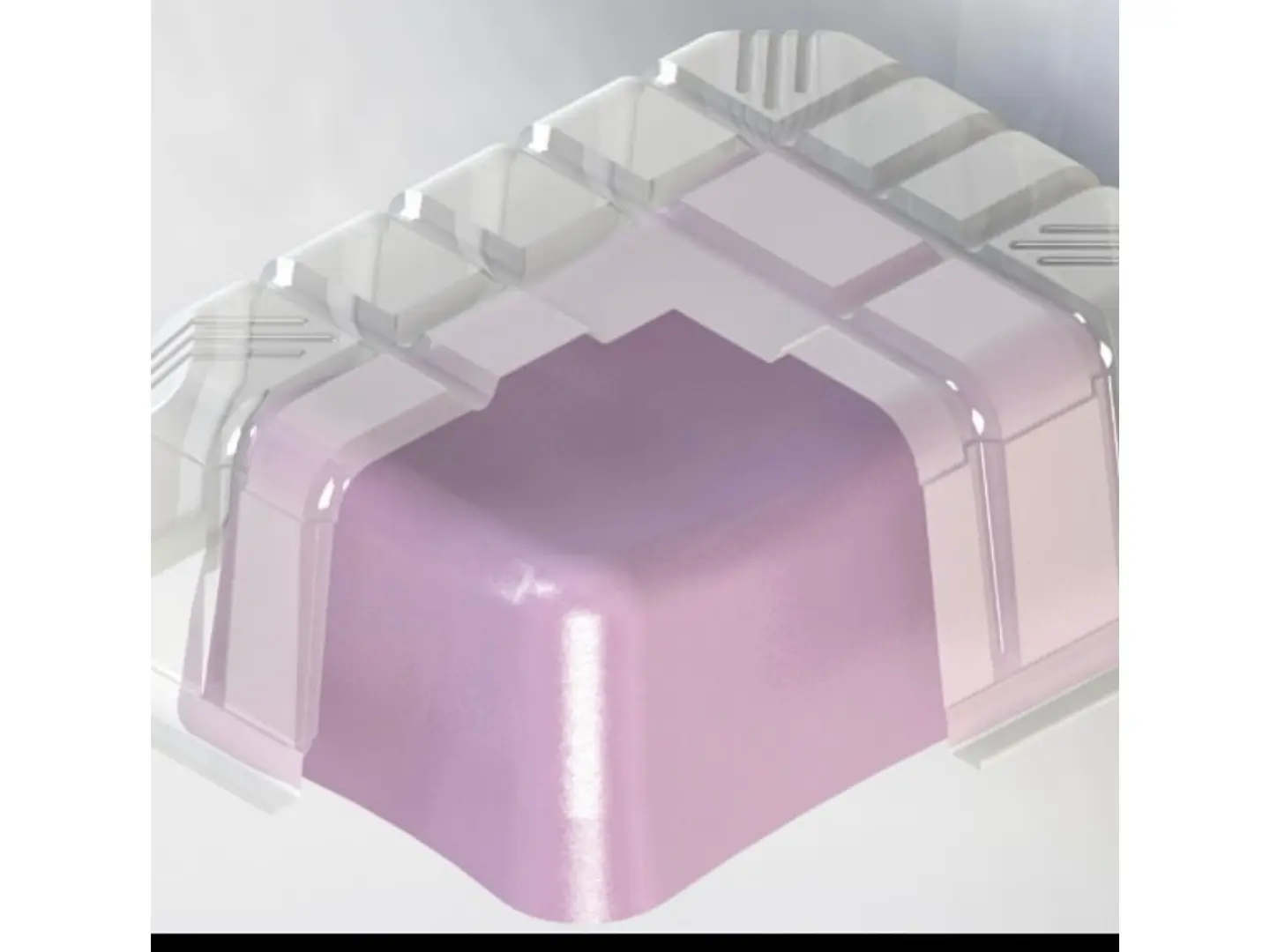

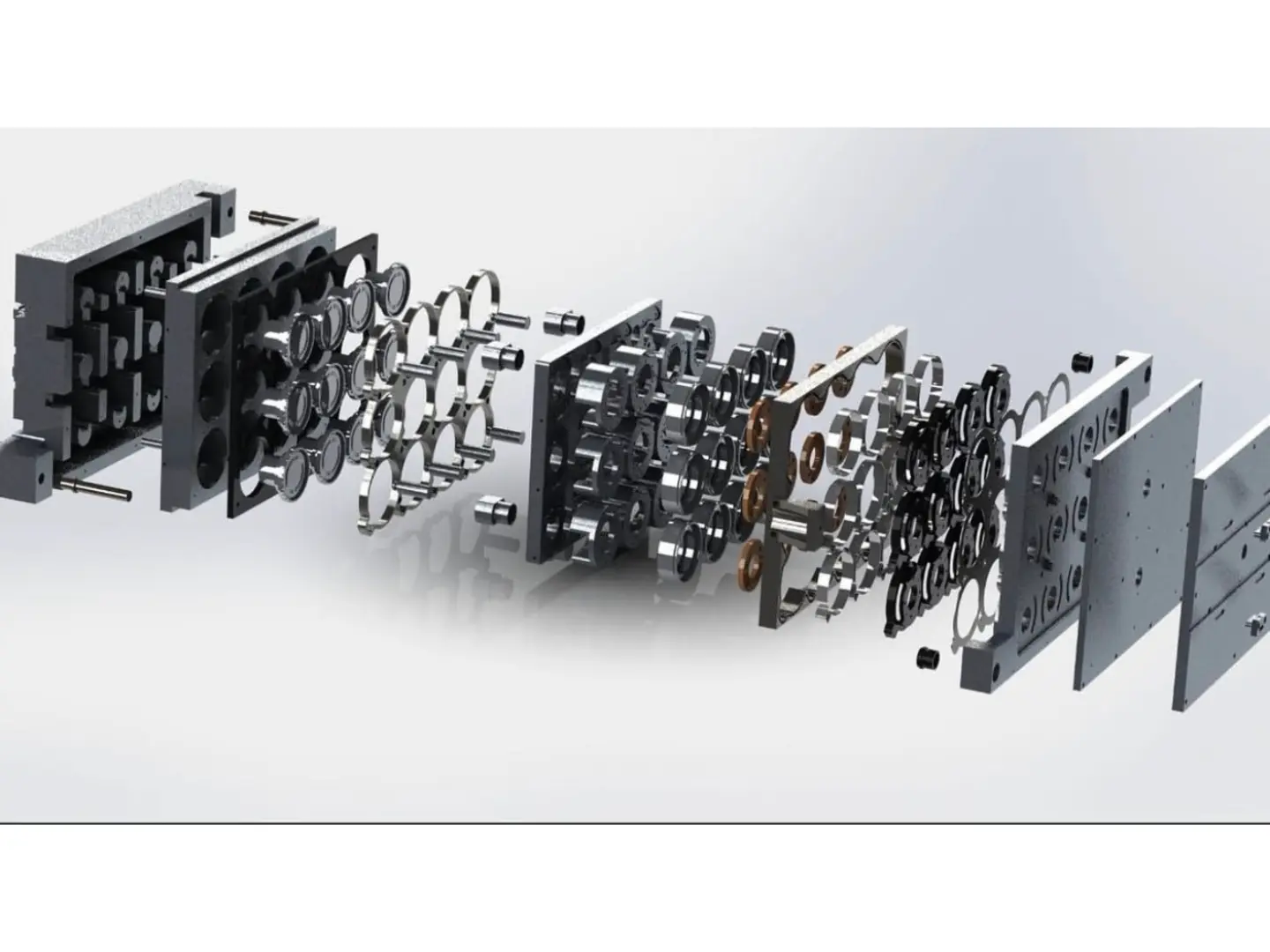

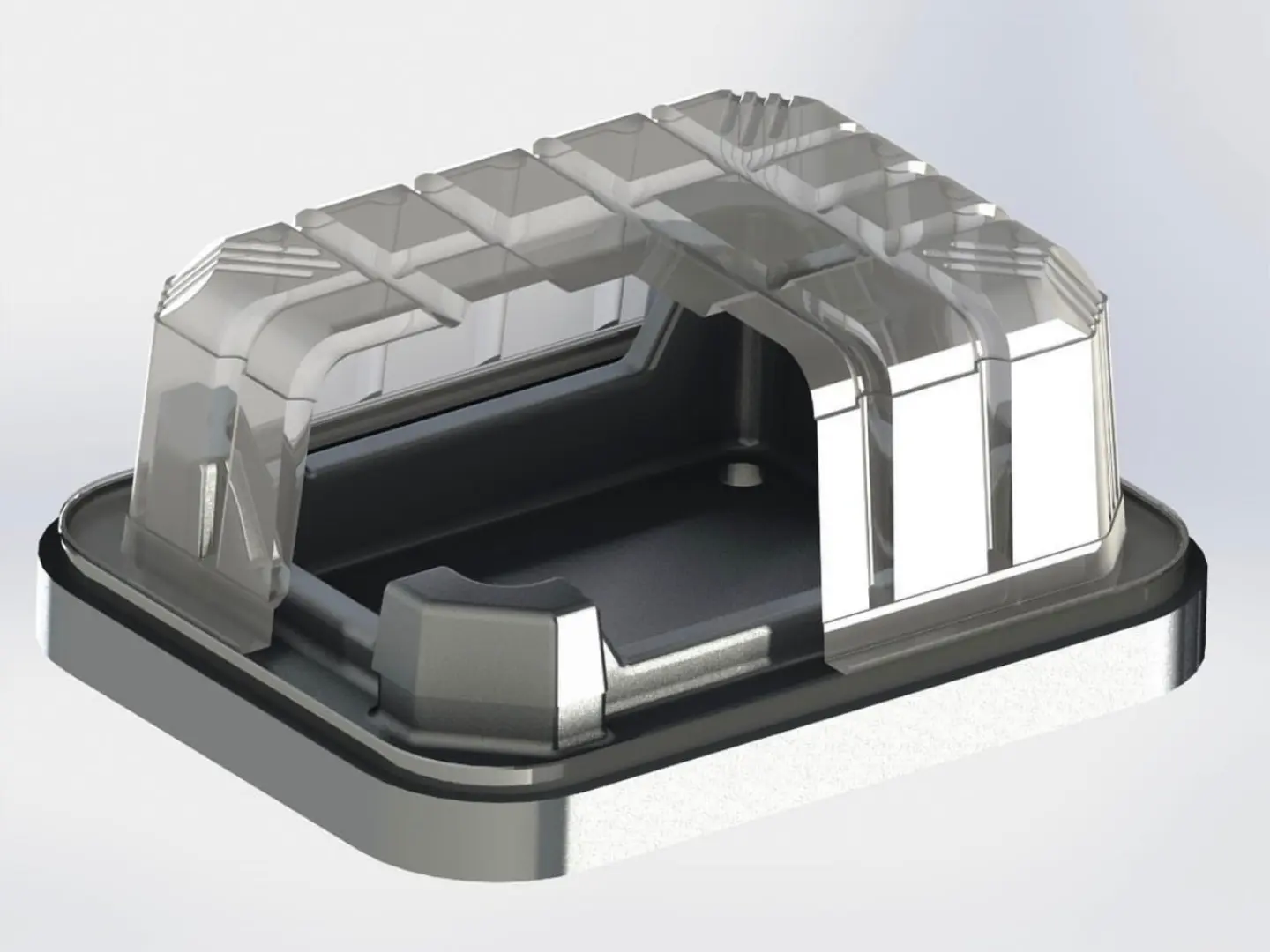

Reverse engineering and design in thermoformed products begin with a detailed analysis of the final product’s geometry, wall thickness distribution, and functional requirements. Existing or target products are evaluated from an engineering perspective to be transformed into measurable, repeatable, and manufacturable structures.

During the design process, the form is optimized by considering draft angles suitable for the thermoforming process, radius transitions, and deformation allowances. This approach ensures both mold compatibility and form stability throughout production.

Contact Us

Let’s Plan the Right Engineering Solution for Your Production

Get in touch with us for your thermoforming machine, mold, sheet extrusion line, and custom project solutions.

- Burç Istanbul Business Center Gökevler Neighborhood, 2312 Street, No:18 Floor: 9 / Office: 85 Hadımköy Junction Esenyurt, Istanbul, Türkiye

- drygonullu@gmail.com

Socials: